What is the difference between high bay and low bay lighting ?

Many people asked the difference between high bay vs low bay lighting, today I would like to answer this question and help you to choose the best bay lights for your application.

Before comparing their difference, let’s figure out their parent category bay lighting.

Bay light refers to any lamps or lighting fixtures applied for large spaces with relatively high ceiling over 12ft in contrast with residential low ceiling.

For residential lighting application, where the roof is under 12ft, we often call it ceiling lighting or ceiling light fixture, which is usually recessed, surface mounted or suspended mounted.

The spaces overhead usually have wood or metal frame or grid and gypsum board to cover it flat in residential house in order to install LED flat panel light or LED Chandelier ceiling lights etc.

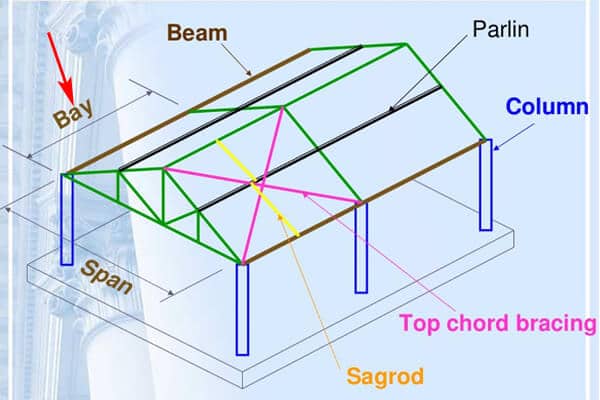

While regarding bay lighting, it is more common to use in commercial and industrial buildings and architectures with high ceiling made of steel, its roof truss spaces overhead is quite large, that is called “bay”.

According to definition of Merriam Webster dictionary, a bay is a principal compartment of the walls, roof, or other part of a building. divided by the transverse arches and adjacent piers of the arcade.

Therefore, you can better understand what a bay lighting is based on that knowledge.

Let’s get started on comparison with high bay vs low bay.

What is high bay lighting ?

High bay light often refer to luminaire installed high ceiling between 20ft to 50ft such as warehouse, hangar, factories, gym, facilities, dairy farm etc.

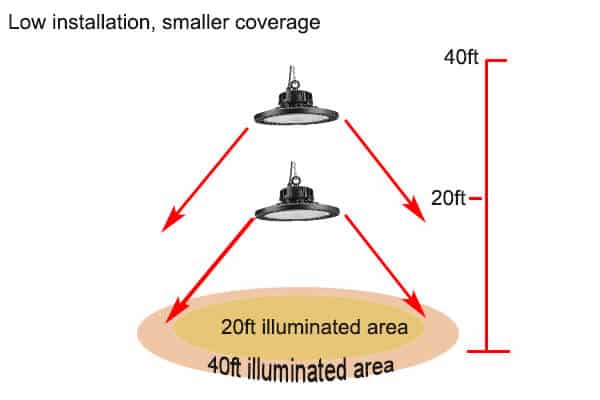

As the light source is a little further from the floor(see demonstration picture below), its beam angle is non-changeable (constant), the higher the fixture is mounted, the more areas it will illuminate on the floor.

Thus, less lumen intensity for each unit area (measured by foot candle=lm/ft² or lux=lm/㎡)

Therefore, sometimes, you might need a 60deg or 90deg aluminum reflector or acrylic lens to direct more light on the wanted ground, narrow the light beam and reduce lumen loss to other unwanted spaces.

This is especially important for task lighting if there is insufficient brightness level for a particular work spaces.

Having a good high bay light will enhance workers’ efficiency, outperform the job completion and boost the production.

That is why business owner should be wise to get notice of its benefits and shift to good quality of LED high bay lights.

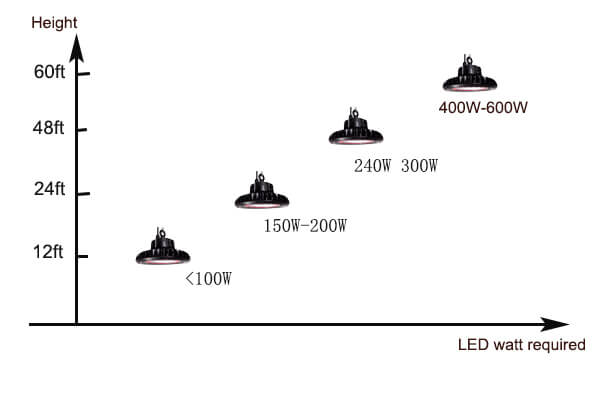

150W-600W is often used as high bay lighting for most project, and UFO style round high bay and linear high bay are the most frequent LED fixtures for this application.

Contact us for quote or for suggestion if you have high bay lighting project to bid.

What is low bay lighting ?

In contrast, low bay lighting is defined as illumination for ceiling height between 12ft to 20ft in retail store or workshop.

It is intended to have wide coverage on the floor, so you can use less fixtures and save your labor fee and installation cost.

Therefore, we don’t need any aluminum reflector most often.

However, that is not an absolute rule.

Sometimes, people will use a prisma clear lens for grocery store or exhibition hall low bay lighting.

Because light should be spotted to certain places, to make the selling items on display more appealing or attractive, no need light up all area evenly.

60W-100W LED UFO high bays or linear high bay fixtures are generally used for low bay lighting,

How to choose LED high bay vs low bay lighting fixtures ?

If there are old metal halide, high pressure sodium bay light in the existing building, the first step you need to do is to look at how many wattage of the original MH HPS lamp, lumen output, beam angle is.

With that info. in mind, you can easily find the right LED to replace it.

In market, the HID (high intensity discharge) include MH, HPS, mercury vapor, and their wattage ranges from 175 watt to 1,000 watt.

Some people think it is good idea to replace the old MH HPS with a new one because it is much cheaper compared with LED upgrade.

That is not a bad solution if your ballast and fixture is still new, you can still have it running for a while.

However, we all know that MH HPS bulb light color will become yellowish after using one year or two, its maintenance cost is quite high.

Therefore, we strongly propose to upgrade to LED instead, as its lifespan lasts over 50,000hrs to 100,000hrs, and it consumes much less energy than HID.

Below are the LED equivalent to the HID for your information.

However, this is not a golden rule also, it can be changeable for different mounting height.

60W LED = 150W-175W HID

80W LED = 200W-250W HID

100W LED = 250W-300W HID

150W LED = 325W-400W HID

200W LED = 400W-600W HID

250W LED = 600W-800W HID

300W LED = 800W-1000W HID

400W LED = 1000W-1200W HID

500W LED = 1200W-1500W HID

600W LED = 1500W-2000W HID

Here, its equivalency, not in terms of its total lumen output, but its foot candle level meassured by lumens per area.

Because HID bulbs lumen efficiency is not as good as LED, there is many lumen output loss due to absorption or reflection on stuff.

After knowing which watt LED high bay or low bay and which beam angle you should go, then you need to figure out your budget

1. wheather you would like to entirely replace the bay fixtures or

2. just replace its light bulb and keep the fixture.

Each has its own pros and cons, respectively.

If you face the situation below, you can replace the whole fixtures without hesitation.

1. The ballast or fixture has been running for quite a period of time, it could be failed in future.

2. You are not satisfied with the energy cost, and want a cut on electricity bill.

3. It affects your manufacturing plant factory worker’s job efficicency, slow down your job completion in your warehouse due to invisibility.

4. You cost many bucks on repairing the HID fixture, don’t want to pay more.

To have all replaced with LED high bay or low bay fixtures is costly in the up front, but it worths the LED upgrade if it helps your business grow, save thousands of dollars each year, and you’ll be happy with the result.

Moreover, if there is DLC rebate program available in your State, that will greatly cut down your expense on LED shift.

Our LED high bay and low bay are DLC standard listed or DLC premium listed, these energy saving certificate will help to apply for rebate.

Below are the LED high bay and low bay retrofit light bulb and light fixtures we have.

Easy to install, remove ballast and screw out the HID bulb and screw in COBs to the socket base.

Another bay light retrofit for downward lighting, easy installation with E26/E39 base, ballast bypass. 35W-400W LED options.

3. LED UFO high bay light fixture

Popular round bay light fixtures to replace fluorescent high bay and low bay light, or metal halide high bay and low bay light in gymnasium, basketball court,dairy farm. Dimmable function or emergency battery backup is supported.

4. LED linear high bay fixtures

Hotly used for classroom, warehouses, office or other conference rooms where the space is long.

5. LED temporary high bay light

Temporary high bay light for construction job site task lighting, portable and linkable one by one, easy to use for contractors.

If you would like to know more lighting solutions for high bay and low bay, you can read Top Four High Bay & Low Bay Lighting Retrofit Solutions

LED Shoebox Light

LED Shoebox Light LED Post Top Light

LED Post Top Light LED Flood Light

LED Flood Light LED Street Light

LED Street Light LED Wall Pack

LED Wall Pack LED Canopy Light

LED Canopy Light LED High Bay

LED High Bay Accessory

Accessory